Safe isolation procedures; have been implemented to certify that workers on the worksite are not exposed to hazards when working on or near live electrical systems. There have been many reports revealing, this safe isolation procedure was not followed or ignored, which caused the loss of lives.

One such report includes a major British power company that has identified unused circuits. The systems engineer does not have the equipment necessary to prove a system’s demise. As a result, he came into contact with a conductor who was still active and killed. The company in question was found guilty of failing to provide the correct equipment and was fined £ 300,000.

The Electrical Safety Council, now called Electrical Safety First, has written a guidance report including best practices for safe insulation. This section of the manual covers the test equipment to be used. Using the right equipment is one of the most significant parts of this procedure. Otherwise, the circuit may remain on and cause injury or death.

Read More: accident attorneys in lehi

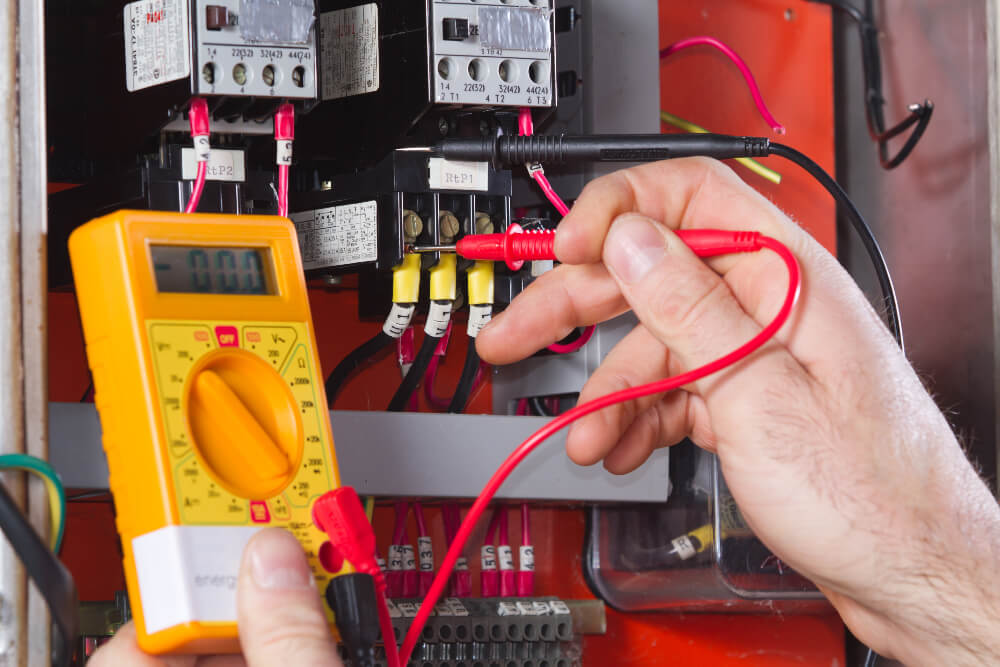

Using various detectors and voltage indicators, we studied the requirements and reasons why some devices, such as a B. multimeter, should not be used for this process.

What equipment needed for safe isolation?

The first electrical safety guidelines state: The isolation point’ must be locked, with a unique key or combination provided by the person performing the job or a designated person and a warning message at the isolation point.

If more than one employee is working on a circuit supported by an isolated distribution board, a multi-locking hook is encouraged to be used to prevent the operation.

Locking kits are available to ensure you have all the tools needed to lock the chain when you are working. There are several kits available in the market, but the basic kit should contain:

Selection of MCB and circuit breaker

Padlock with a unique lock or combination

Speed up when more than one person is working on a system

Key-labels and warning signs

Note that padlocks must have a unique key or combination. It must be respected; by the person doing the work to prevent others from opening the lock and accidentally activating the chain. Most combination locks have a default setting of zero. When using this type of lock, be sure to change the combination before using it.

Once the switches are correctly connected, warning labels; should be placed to make it clear; that the circuits are interconnected and in operation.

The perfect chain lock is only part of the process. Before doing any work on the circuit, you should check it is simply dead before proceeding. Chains are often’ mislabeled, so there is no certainty that the correct chain is locked. To do this, you need to use a specific voltage indicator and a check unit.

The guideline makes some points related to the use of the tension indicator off. Some of the most important are:

After removing the device or circuit and before starting work, you should be sure that the part to be processed and around it is dead. Devices should not be assumed dead, as they turned off actually.

So it is not enough to lock the circuit breaker and assume that the circuit is dead. There are instances when the neutral is busy, and unfortunately, although BS7671 does not allow this, it is not uncommon. In this case, although a circuit can be blocked, a neutral conductor can be connected if the energy load of another “circuit” connects to it.

Above mentioned recommendation are precautionary measure which can reduce the risk of life loses.

Melissa Day is a dedicated home blogger who has been blogging for over six years. She covers everything home related. Melissa also loves writing posts about her travels to Europe with her husband and two children.